Foam glass insulation board is one of the building materials that are often used in decoration. It is not easy to deform and has high corrosion resistance. However, many users still do not understand foam glass. Next, ZES will solve your doubts, let us understand together What material is foam glass, what are the characteristics and production principles of foam glass, and what are the uses and application fields of foam glass?

Also known as cellular glass or foam glass. It is a kind of insulating glass with a porosity of more than 90% and composed of uniform pores. Because its pore structure has the physical properties of borosilicate, it is used as a thermal insulation material with the characteristics of airtightness, no combustion, no deformation, no deterioration, and no food pollution. Therefore, it is not only used for indoor and outdoor non-combustible thermal insulation It is also used in food freezing fermentation and brewing equipment, buoys of liquid level meters, etc. The production of foamed glass adopts the powder sintering method. The foaming agent is added to the glass micropowder and mixed, heated in a heat container, expanded and then annealed to obtain the finished product.

Foam glass was first invented by Corning in Pittsburgh. Inorganic non-metallic glass materials. It is composed of a large number of uniform bubble structures with a diameter of 1 to 2 mm. Among them, the sound-absorbing foam glass is more than 50% open-cell bubbles, and the insulating foam glass is more than 75% closed-cell bubbles, which can be adjusted by changing the production technical parameters according to the requirements of use.

Because this new material has the functions of moisture-proof, fire-proof and anti-corrosion, and the glass material has the advantage of not deteriorating in long-term use, it can be used in harsh environments such as thermal insulation, cryogenic, underground, open air, flammable, moisture-prone and chemically eroded. It is favored by users. It is widely used in wall insulation, petroleum, chemical industry, computer room noise reduction, highway sound-absorbing partition wall, electric power, military products, etc. It is called green environmental protection thermal insulation material by users.

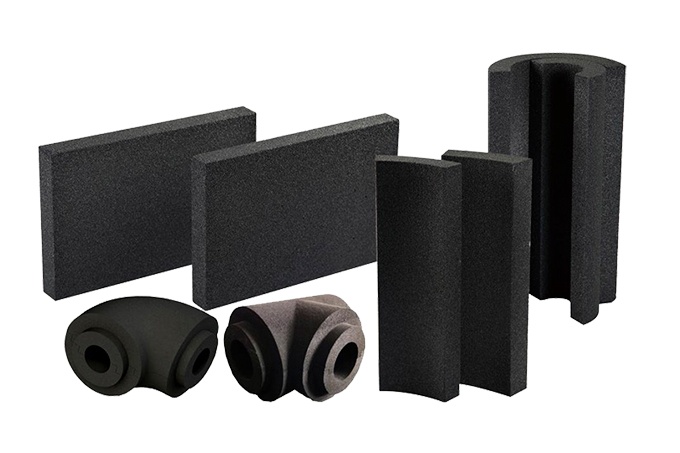

According to the various properties of foam glass, it can be used as a thermal insulation material in various sectors of construction engineering, as well as in shipbuilding, chemical industry, low temperature and high temperature technology. White and stained glass are also used as sound-absorbing and decorative materials. The waste in production - foam glass powder and scrap can also be used as filler for decorative lightweight concrete and other purposes. According to different uses, the foam glass products produced by the corresponding process can be divided into four categories, namely thermal insulation foam glass, sound-absorbing decorative foam glass, decorative foam glass and granular foam glass.

1. The basic material of foam glass is glass, so there is no need to worry that it will be soaked by water. In addition, the bubbles inside the glass are also encrypted and closed, and there will be no capillary phenomenon in ordinary glass, nor will it be penetrated. Combining these two points, foam glass is currently the most ideal cold and thermal insulation material.

2. It has high mechanical strength, and the change of mechanical strength is proportional to the apparent density. Compared with other materials, it can withstand the erosion pressure and gravity extrusion brought by the external environment due to its good compressive properties. Therefore, the combination of mechanical strength and moisture resistance makes foam glass widely used in underground pipeline construction and tank foundation construction.

3. Thermal insulation foam glass has good thermal insulation and moisture permeability, because its own thermal conductivity can be in a stable stage for a long time, and it is very little affected by changes in external environmental factors. Good thermal insulation performance.

4. Sound-absorbing foam glass has good sound insulation performance and has a strong absorption effect on sound waves. According to research and analysis, after sound waves in the range of 60-400Hz penetrate sound-absorbing foam glass, the average loss reaches 28.3dB.

5. Because foam glass has good dyeing properties, it has become a wide range of thermal insulation decoration materials in the decoration industry.

Foam glass is a lightweight and high-strength building material and decorative material with excellent thermal insulation (cold insulation), sound absorption, moisture resistance and fire resistance. Although other new thermal insulation materials emerge in an endless stream, foam glass occupies an increasingly important position in the fields of low thermal insulation, moisture-proof engineering, sound absorpt ion, etc. due to its permanence, safety and high reliability. Its production is the reuse of waste solid materials, which is an example of protecting the environment and obtaining substantial economic benefits.

1. It is non-toxic, non-radioactive, will not release harmful substances, will not pollute the foundation and groundwater, and is an environmentally friendly material;

2. Non-combustible, low moisture absorption and water absorption rate, and use temperature range, the actual use temperature of ordinary foam glass is 240~280 ° C;

4. The bulk density, open and closed porosity and other properties can be adjusted by changing the formula and foaming process;

1. In the production process of foam glass, bubble defects such as uneven bubble structure or large bubbles are often encountered. The large bubbles of foam glass are mostly circular or oval, and most of the bubbles appear in the center and edge, and the pore size is in the range of 10-100 mm.

2. The generation of side holes, side holes refer to irregular holes on the outer side of the foam glass blank product, the diameter or depth of which can reach 30mm, which will affect the yield of the product and its cutting rate.

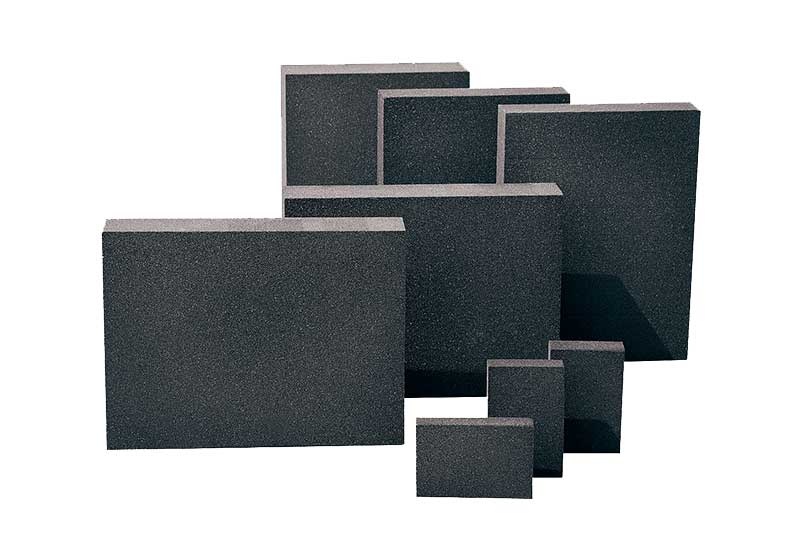

1. The bulk density of the foam glass insulation board is light, about 160kg/m;

2. The thermal conductivity is small, below 0.058 w/m*k, and the thermal conductivity is stable;

3. Impermeable to moisture;

4. Low water absorption, about 0.2%;

5. Does not burn;

6. No mildew and corrosion;

7. High strength, compressive strength ≥0.7Mpa, flexural strength ≥O.5Mpa;

8. Resistant to acid corrosion (except hydrogen fluoride);

9. It is non-toxic and does not contain CFC (chlorofluorocarbon) and HCFC (hydrofluorochloric acid);

10. Stable physical and chemical properties, stable size, easy to cut

Foam glass panels are widely used in petroleum, chemical industry, underground engineering, In the fields of national defense and military industry, it can achieve the effects of heat insulation, heat preservation, cold preservation and sound absorption. In addition, it is also widely used in the thermal insulation of external walls and roofs of civil buildings. With the increasing requirements of human beings for environmental protection, foam glass will be It has become an advanced wall insulation material and roof insulation material for urban civil buildings. With its inorganic silicate material and independent closed tiny pores, foam glass brings together airtight, non-combustible, anti-gnawing and moth-proof, acid and alkali resistance (except hydrofluoric acid), non-toxic, non-radioactive, chemically stable, and easy to process. Moreover, it has the characteristics of no deformation, and its service life is equivalent to the service life of the building. It is a safe, reliable and durable building energy-saving and environmental protection material.

1. Petrochemical: reaction equipment, chemical pipelines, oil pipelines, liquefied natural gas pipelines, storage tank foundations, and liquefied petroleum gas pipelines.

2. Construction: cold storage, shipbuilding, roof insulation, inner and outer wall insulation, parking lot, floor screen, environmental protection chimney lining insulation.

3. Underground engineering: subway, underground warehouse, tunnel.

4. Other industries: national defense industry, grinding stone, teppanyaki cleaning brick, low temperature pipeline of air separation equipment, low temperature liquid storage tank, basic insulation.

The popularity of foam glass is inseparable from its own advantages and good energy saving and environmental protection performance, which is also inevitable.

ZES is the biggest foam glass(cellular glass) producer in Asia and the most competitive insulation contractor in China. For many years, ZES has kept a long-term relationship with major industrial players in China, covering more than half of the domestic market share of cold insulation. ZES is also playing actively in the global market, with its service to major oil & gas owners and EPC contractors worldwide.

If you need above products, feel free to contact us, send your email to trading1@zhenshen.cn, we will reply to you as soon as possible.